HAN Eco Marathon

The HAN Eco marathon is a student event organized by the HAN

University of Applied Sciences. The objective of the event is to design and

produce a car that can travel the furthest distance for each gram of CO2

produced. The powertrains allowed were combustion engines and electric

drivelines. The car is supposed to be designed under certain rules which exist

for the safety of the drivers, spectators and the engineers making the

vehicles. The teams have a limited budget of 1000 euros and all the teams are

allowed one testing day at the circuit and the main event took place at the

Lelystad circuit in the Netherlands.

Maximizing efficiency was the objective of our team we had

to have the largest distance travelled per gram of CO2 expelled. The team made

the choice to use an electric driveline due to the higher efficiency of the

electric motors as compared to combustion engines. The CO2 use for electric

vehicles was calculated by seeing the energy consumed and then calculating the

CO2 that is produced to make the energy.

My role in the team included leading a small team which made

up the chassis and body department. Our job was to design a lightweight chassis

and an aerodynamic body with least amount of aerodynamic drag. We worked by

looking at ways reduce losses like air drag and rolling resistance. The basic

concept we came up with was a 3 wheeled vehicle with 2 wheels in the front and

1 in the back with the electric driveline. We chose a driver and decided to

make the vehicle around him to make the vehicle as compact as possible.

We initially decided on making a lightweight spaceframe for

the vehicle with steel tubes. After

making our design on Solidworks and doing analyses we realized that the steel

tube chassis was too heavy. We discussed the option to use aluminum instead of

steel, however, that idea was scrapped as aluminium tubes would be too costly

and since no one within the team knew how to weld aluminum it would add to

costs if the chassis welding had to be outsourced. With a limited budget it was

not possible to make this happen.

We decided to consult teachers who could help us reduce the

chassis weight of the vehicle, some teachers suggested simplifying the

construction or using wood in the vehicle. One of our teachers suggested that

we could save a lot of weight by using a sandwich panel. We agreed this was a

great idea and decided to make the base of the chassis with a sandwich panel.

This meant we did not need a floor piece for the body. We used the partial

spaceframe along with the sandwich panel to mount the rear and front wheels and

steering system. We used a sandwich panel of wood skins and a foam core.

The steering system we used for the vehicle was one like the

one used in go karts. The front wheels were 20-inch bicycle wheels and the rear

28-inch bicycle wheel. We used disc brakes for the front wheels and on the

rear, we used bicycle v brakes.

The chassis and powertrain department worked hand in hand

and while the chassis department was busy the powertrain department designed

the driveline for the vehicle, we had chosen to go with a wheel motor like the

ones that are present in electric road bikes. Along with a 36V battery system.

One of the mandated parts were the batteries, they were

provided by the university and they were lead acid batteries of 12V. Therefore

we had to use 3 batteries. Once the chassis and powertrain were finished the

body was designed. It was decided the body would be streamlined to reduce air

drag with separate wheel covers on the front wheels to reduce the drag around them

as well.

The production process of the vehicle was the most

challenging part of the entire project. It was here we realized that the design

we made was not too simple and would challenge us. One of the biggest changes

came from the choice of drivers. We had decided to switch drivers and go for a

lighter driver; the said driver however was taller which would lead to changes

in the design.

Immediately the packaging of the entire vehicle was changed.

The sandwich panel had to be made longer and the steering interfered with the

drivers legs. This was not allowed and was stated in the rules therefore

changes had to be made. Several design changes were made during the production

process and that was costing us a lot of time. We were behind several teams in

production and in the end that became too much.

Testing day arrived and the vehicle we had made was heavier

than expected and therefore failed the braking scrutineering, the steering

radius of the produced vehicle was too much. Since the vehicle was not fit for

the track the team decided to not to go for testing. This was a big blow for

the team and the morale. The main race was only 2 weeks away, all other teams

had a day of testing and our team had a vehicle that was yet not fit for the

track.

It was a tough time

for the team but we had a meeting to discuss our options. And the only choice

was to tackle our issues from the bottom up and work hard. The team went full

steam working from 6am to 12 midnight for the 2 weeks.

We decided to change the vehicle dimensions, the height of

the vehicle, the drivers seating position steering positioning and even the

amount of batteries to use. The amount of batteries to use was changed because

using 36V the vehicle was not reaching required speed after a certain amount of

time, that wasn’t enough for the vehicle to do the 3 runs required by the

competition. All these changes added weight and made the vehicle less compact

but we were running the risk of not making the vehicle in time for the race so

we agreed to allow these compromises.

We put 2 V brakes in

the rear wheel to make sure the vehicle can brake because of its added weight.

After working for more than 1 week for around 16 hours a day our chassis was

ready for the scrutineering. We were all very nervous but our hardwork paid off,

we passed the scrutineering. The chassis was ready to hit the track and the

driveline was ready too. However, the by-product of the changes was that since

the dimensions had changed significantly due to that the body had to be

redesigned. The body was redesigned and and then some members of the team

produced the mold with wood and gave the mold to a company that specializes in

fiberglass bathtub production.

After all this work the body was ready only 2 days before

the race and everything was mated together only 1 day before the race. We put

our sponsor stickers on the vehicle and tested it one last time on the night

before the race and let the batteries charge till morning.

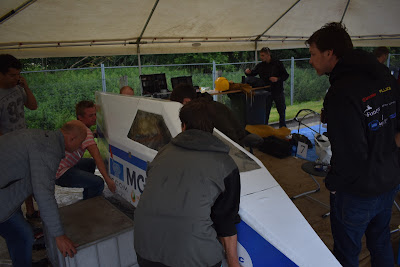

Raceday arrived and it was a completely different story, we

arrived at the circuit in Lelystad and it was pouring down. This was a problem

for he teams taking part in the event because the sun had been shining the

entire week and the forecast was for a sunny day. None of the teams had done

water proofing to their vehicles. So when the teams arrived to the paddock

everyone got to work on waterproofing their vehicles. Thankfully our car was

waterproof and all our electronics were safe from the rain and puddles on

track. Raceday was very hectic and the first few teams went out on track to put

the heats in, immediately we realized what a big problem the rain was going to

be. Two of the first four teams that went out had problems with their electric

systems.

We went out to set our first run and everything was going

well, unfortunately 3 laps before the end of our heat we got a tire puncture

and had to retire before the end of the run. We got back to the pits and

replaced the tires. We also made a few holes around the windshield of the

vehicle since visibility was poor due to the rain. After making these changes

we went to make our second run. The second run went much better than the first

and we were able to finish our heat. However, once we got to know out result,

we weren’t too pleased we had a score of 165 km/l from the second run which put

us in 5th place overall. This was much less than what we had

predicted for our vehicle. Since there wasn’t much we could change within the

limited time frame between the runs we decided to make small changes.

We decided to swap our batteries for ones that were fully

charged, we did that by swapping the batteries with one of the teams that was

unable to take part in the event any further because their electronics were

short due to the rain. With the fully charged batteries we went for the third

run with a different driving strategy. This run we carried more speeds into the

corners and accelerated slowly to maintain the required average speed. The

third run was much better and when we finished and saw the result we were quite

pleased that our efforts had come to fruition. We had a score of 285km/l. This

moved us right up to 3rd place.

We decided to keep working on the vehicle, improving the

alignment and the driver strategy for the final run. We went for the final run

and decided to carry even more speed through the corners so that the

acceleration required on the straights is even less. 2 laps before the end of

our run disaster struck the left wheel had a big wobble and while going through

one of the corners the spokes of the wheel broke and bent and the rim lost

shape. This meant that we had to retire and the we couldn’t finish our last

run. This was a shame for us as this run would’ve brought our average score

much higher. Our average score was now taken from the second and third runs. This

meant that we finished 4th of the 7 teams.

At the end of the day, the team was quite disappointed with

the result and personally so was I. Most of the other teams had the goal to

just pass the project and the teachers and fellow colleagues watered down

everyone’s ambition. I personally wanted to win the event and that was my goal.

That didn’t happen so naturally I was very disappointed.

As time passed, I realized what a great learning experience

this was for me. Success and failure can both be great teachers and I learnt a

lot through these few months than the previous few years. I plan to take what I

learnt from this experience and be a successful engineer and learn from the

mistakes made here so that I don’t make the in the future and consequently achieve

the goals I have for myself and the goals of the team or company I am a part

of.

I found the variety of steel tubes here impressive! The quality and finish are excellent, making it a great choice for both industrial and DIY projects.Read more info about Roof Edge Protection

ReplyDelete